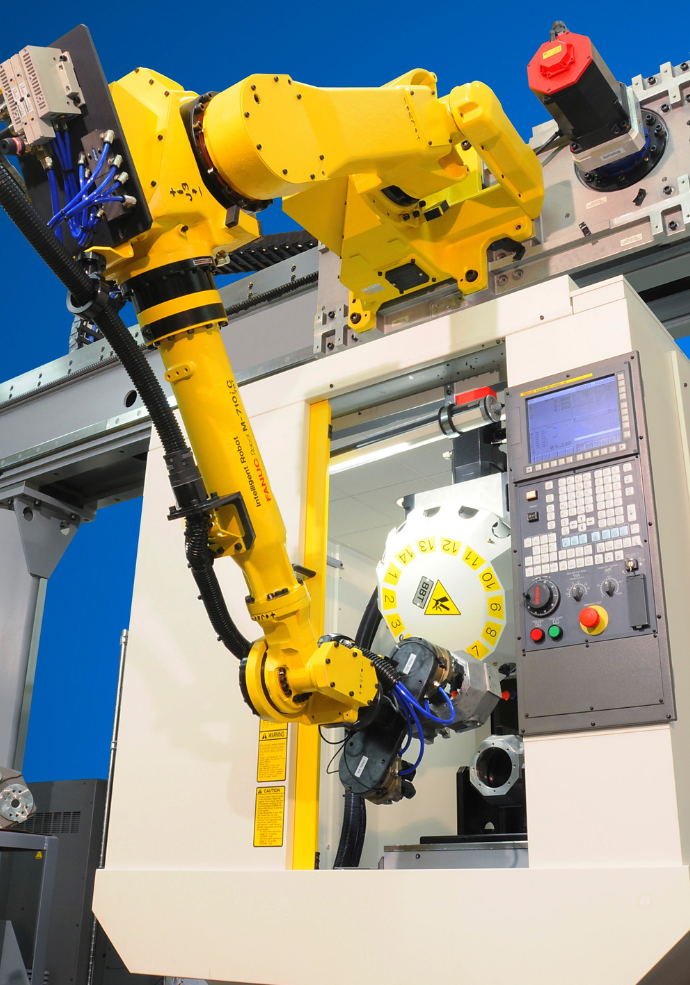

Robotic arms, at the central point of modern production and manufacturing, are changing the norms in a way previously thought to be not possible. They blend high-quality, safety and efficacy. These mechanical marvels, often referred to as robot arms, have become essential in all industries driven by the urgent necessity to cut operating costs and maintain high standards of quality. Robotic arms are being integrated into production lines in order to reduce costs and increase safety. Explore how these innovative machines have transformed the landscape of industrial production.

Image credit: automatedsolutions.com.au

The primary force behind the global surge in robotic arm adoption is cost efficiency. The demands on factories to cut down production mistakes, material waste and workplace accidents is relentless. Robotic arms face these challenges head-on. In contrast to human workers, robotic arms can perform repetitive tasks with pinpoint precision which eliminates costly errors and reducing waste of raw materials. For high-volume industries, like automotive manufacturing, robot arms ensure perfect assembly through precise welding and parts positioning. This accuracy can translate into significant savings since fewer damaged products means less work and waste.

The security of robotic arms is also an important element. There are many manufacturing processes that require handling dangerous materials or operating large machinery pose risks to human workers. Utilizing robot arms, firms can shield employees from these hazardous areas, greatly cutting the possibility of injuries sustained in the workplace. Robotic arms are comprised of a number of movable joints that replicate the human arm’s functions. But, they work without danger of injury. Equipped with hand end effectors, these devices can accomplish tasks that could be hazardous for humans, like welding or spinning.

Robotic arms can be a game changer in various industries due to their adaptability. Robot arms are adaptable to many different tasks. From assembly for automobiles to electronics production. Because they are programmeable, they can to execute complex tasks, such as tending machines, painting, or fiberglass application with unparalleled reliability. Robotic arms have revolutionized the palletizing process in warehouses, allowing it to be automated with speed and precision. Automation not only improves efficiency however, it also improves reliability because robot arms are able to perform their work without fatigue.

The growth of cobots (collaborative robots) which work in conjunction alongside human employees is one of the most thrilling advancements in this field. Cobots that have robotic arms, unlike conventional industrial robots that are isolated in cells, are specifically designed to be able to communicate with humans securely and seamlessly. Cobots with robotic arms can perform difficult or repetitive lifting tasks in factories and allow human workers to focus on more challenging duties. The collaboration improves productivity and ensures a safe work environment, as cobots are programmed to stop or adjust their movements if a human is nearby.

Robotic arms have an enormous impact on modern manufacturing, and not just in terms of safety, but also efficiency. The ability robotic arms to carry out tasks with great accuracy like welding, material handling or assembly, has made them indispensable for industries where safety is the top priority. For example, in automotive manufacturing, a robot arm can rotate and position parts during assembly, ensuring an exact alignment with no human intervention. In the field of electronics, robots can be used to handle delicate components, which decreases damage and improves output quality.

Robotic arms are likely to grow in importance as industries evolve. Because they are able to cut costs, improve safety, and adapt for different tasks, robotic arms are the core of the future of manufacturing. Combining cutting-edge technology with human creativity, robotic arms are more than instruments. They are partners that drive innovation, transforming how we construct our world.